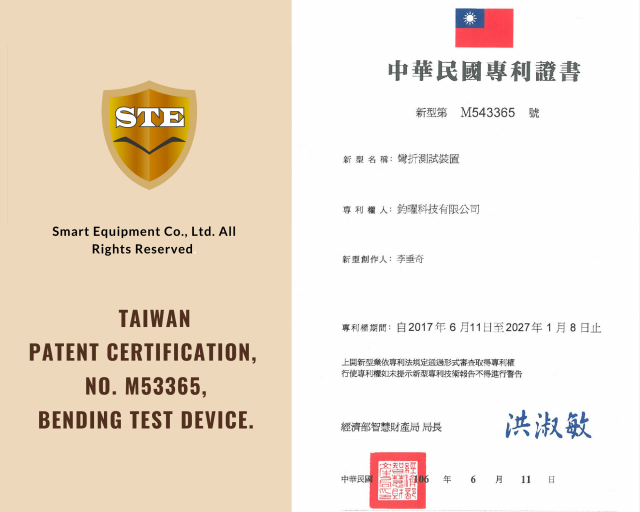

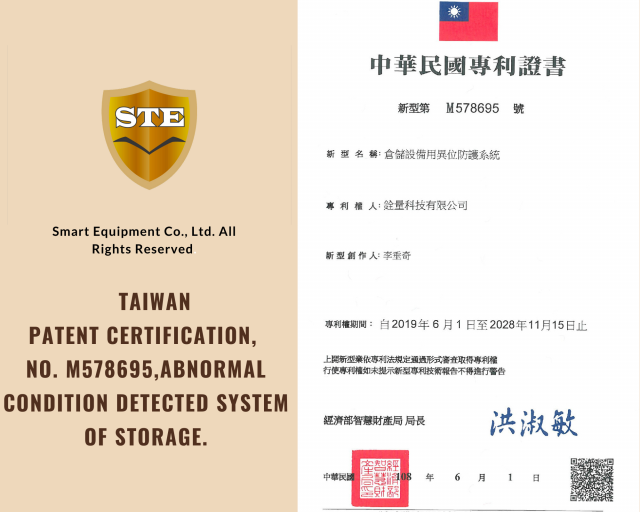

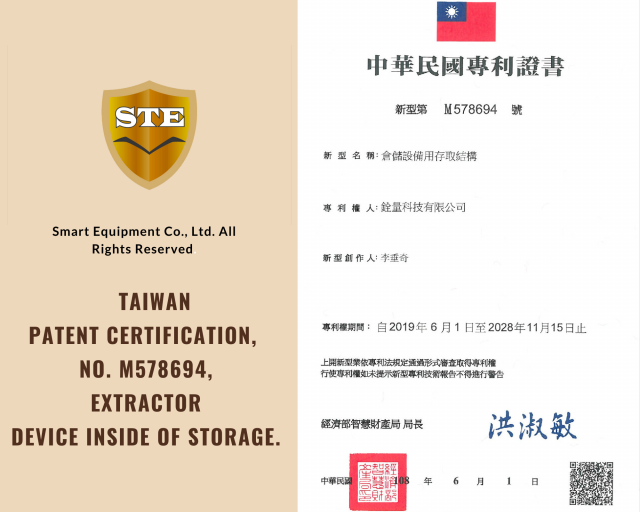

Patent

In order to gain the trust and satisfaction of customers, Junyao Technology obtained ISO9001:2015 quality system certification in 2019, and always listens to customers’ opinions and understands their needs, provides customers with high-quality products and a full range of considerate services, and is committed to the industry Contribute and set the quality policy to implement thoroughly, and continue to improve to maintain the effectiveness of the quality system.

1.Maintain the original soft and hardware design of smart storage, but choose low-dust materials for dust-prone components.

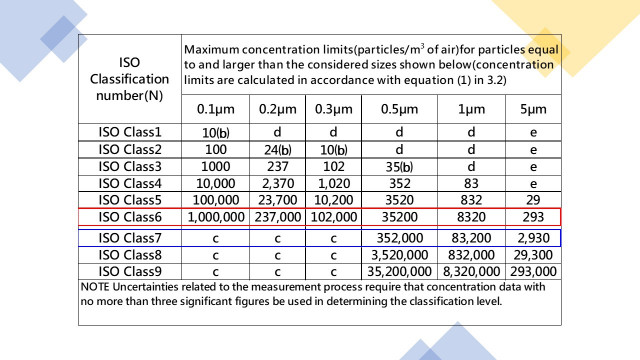

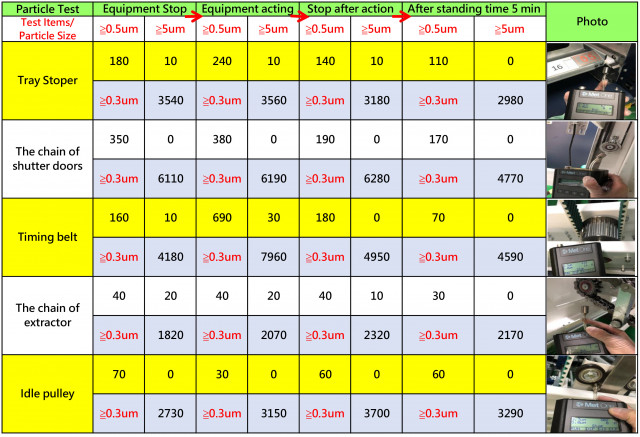

2.Test conditions for dust generation in clean room:

Under the conditions of (1) the machine is stationary, (2) the machine is in motion, and (3) the machine is still in motion, the 0.5um & 5.0um dust generation test is carried out on the dust-prone components, and the results are in line with Class1000 (ISO 6) Specification. 3. Considerations for smart storage construction: (1) Confirm the air flow field in the clean room in advance, (2) Provide recommendations for optimizing the flow field of the working environment, (3) Confirm the flow field of the smart storage itself in the working environment, ( 4) Small changes in demand for improving airflow inside the exclusive customized warehouse, such as adding a transparent dust cover, etc.

Apex Equipment CO., LTD.

TEL:04-23845678

FAX:04-23863079

ADD:No. 5-17, Wenshan N. Ln., Nantun Dist., Taichung City 408019 , Taiwan (R.O.C.)

Email:ste@jyste.tw

FAX:04-23863079

ADD:No. 5-17, Wenshan N. Ln., Nantun Dist., Taichung City 408019 , Taiwan (R.O.C.)

Email:ste@jyste.tw

銓量科技有限公司

統編 60233881

鈞曜科技有限公司

統編 42876046

統編 60233881

鈞曜科技有限公司

統編 42876046

TOP